Views: 0 Author: Site Editor Publish Time: 2025-07-14 Origin: Site

A scissor lift is a kind of mobile elevating work platform. It helps people reach high places safely. The platform goes straight up. It does this by stretching crisscrossed steel beams. These beams keep the platform steady and flat. You can see a scissor lift at construction sites. They are also used in warehouses and for fixing equipment. The global market for scissor lifts is growing quickly. There is strong demand in construction, warehousing, and logistics.

Sector | Usage & Growth Drivers |

|---|---|

Construction | 50.7% revenue share, infrastructure |

Warehousing | E-commerce, safety, logistics |

Industrial | Manufacturing, heavy equipment repair |

Jieyang Machinery gives you good solutions for aerial work platform needs. They also help with elevated work platform needs. They offer manual material lifts and stackers.

A scissor lift lets people go up high safely. It lifts a platform straight up with crossed steel arms.There are many kinds of scissor lifts. Electric ones work best inside. Hydraulic ones are for heavy jobs outside. Manual lifts move light things and do not need power.Scissor lifts have safety parts like guardrails, sensors, and emergency stops. These help keep workers safe when using them.You must pick the right scissor lift for your job. Think about how high you need to go. Think about how much weight you need to lift. Also, think about if you work inside or outside.You need good training to use a scissor lift. You should check the lift often. Always follow safety rules to keep scissor lifts safe and working well.

When you know how a scissor lift works, you see why it is safe and helpful. The scissor lift uses crisscrossed arms to move up and down. These arms are called the scissor lift table mechanism. When you turn on the lift, cylinders push the arms apart. This makes the platform go up. The X-shaped design is called a pantograph. It keeps the lift steady and spreads out the weight as it moves.

Modern scissor lifts have many safety features. Guardrails and gates stop you from falling. Toe guards and sensors stop the lift if something is in the way. Overload and tilt sensors keep the platform level and safe. Emergency stop buttons and manual controls help if there is a problem. Alarms make sounds and flash lights when the lift moves. These features help keep workers safe on the job.

Scissor lifts can use different power sources. Hydraulic systems are strong and last a long time. Electric lifts are quiet and do not make smoke, so they are good for inside. Pneumatic lifts use air and are good where leaks are a worry. Here is a quick comparison:

Power Source | Best For | Advantages |

|---|---|---|

Hydraulic | Outdoor, heavy-duty | Powerful, durable |

Electric | Indoor, clean settings | Quiet, low maintenance |

Pneumatic | Sensitive environments | Energy-efficient, safe |

A scissor lift has several main parts. The scissor arms are made of strong steel and hold heavy things. Hydraulic cylinders move the arms up and down. The lift table is where people or things stand. The base platform keeps the lift steady. Wheels let you move the lift. The control system helps you use the lift safely.

Scissor lifts can have some common problems. Hydraulic leaks or slow movement can happen. Electrical problems might stop the lift from working. Control system issues can make the lift not respond. Strange noises or shaking can mean something is wrong or too heavy. To fix problems, check the fluid, look at the wires, test the controls, and check for damage. Doing regular checks and maintenance helps keep your scissor lift safe.

Tip: Always follow the maker’s maintenance plan for your manual material lift, stacker, or scissor lift. This helps your equipment last longer.

When you pick a mobile elevating work platform, you have choices. Each type works best for certain jobs and places. Here are the main types you might see:

An electric scissor lift is good for indoor use. It does not make smoke, so air stays clean. The lift is quiet, which is nice for schools and hospitals. You do not have to worry about loud sounds or bad smells. Electric scissor lifts are easy to use and need little care. They have fewer parts that can break. These lifts work well for light jobs on flat floors. But, the battery only lasts so long before you must charge it. They cannot carry as much weight and do not work well outside on rough ground.

Tip: Pick an electric scissor lift for indoor jobs where you need clean air and quiet.

A hydraulic scissor lift uses fluid to move up and down. It can lift heavy things, so it is great for big jobs outside. The lift moves smoothly, even with large loads. You can use it in warehouses, factories, and on building sites. Hydraulic lifts work better than electric ones on rough ground and can go higher. You need to check the fluid and do some care, but you get more power for hard work. Some lifts use diesel engines for even more strength outside.

Feature | Electric Scissor Lift | Hydraulic Scissor Lift |

|---|---|---|

Emissions | Zero | May make smoke |

Noise | Quiet | Louder |

Weight Capacity | Lower | Higher |

Best Use | Indoor, smooth floors | Outdoor, heavy-duty tasks |

A manual material lift does not need power or fuel. You use your hands to work it, so it is simple and cheap. It is good for light loads and jobs you do not do often. You can use it where there is no power or when you need to move it a lot. It is easy to care for, and you do not need to charge it or check fluid. This lift is good for small shops, workrooms, and jobs with less money.

Manual material lifts are flexible and save money.

You can move them easily and use them in many places.

Jieyang Machinery has many lifting tools. You can get manual material lifts, stackers, hand winches, and small aluminum lifts. These tools help you move things safely and quickly in many jobs. Jieyang Machinery makes each tool strong and easy to use. If you need a scissor lift, hydraulic scissor lift, or other tool, Jieyang Machinery has what you need. Their tools help with building, fixing machines, and storing things in warehouses.

Note: Jieyang Machinery’s stackers and hand winches give you more ways to lift and move things.

Scissor lifts are used in many jobs and industries. They help people reach high places safely. Ladders or scaffolding can be hard to use for some tasks. Scissor lifts make these jobs easier and safer. Here are some ways you might use a scissor lift.

Scissor lifts are common on building sites. They help workers reach ceilings, roofs, and tall walls. You can use them for painting or putting up lights. They are also good for fixing HVAC systems. The platform is steady, so you can use both hands. You can bring tools and materials with you. Scissor lifts are safer than ladders because they have guardrails. You can move the lift to new spots fast. This saves time on the job. Many teams pick scissor lifts for safety and speed.

Tip: Check the ground before you use a scissor lift. Make sure it is flat and has nothing in the way.

In warehouses, scissor lifts help you reach high shelves. You can use them to pick items or count stock. They help you move goods and rotate inventory. Using a scissor lift can save time and make work more accurate. Studies show they cut inventory time by 40%. They also make counting more correct by 22%. Scissor lifts are small enough for narrow aisles. You can use a stacker or manual material lift for lighter loads. These tools help you work faster and safer. They keep you steady and lower the chance of falling.

Some warehouse uses are:

Picking orders

Restocking shelves

Checking the building

Fixing equipment

You can use scissor lifts inside or outside. Pick the right type for your job. Electric scissor lifts are best for indoors. They are quiet and do not make smoke. Their small size helps in tight spaces like stores. For outside, use a diesel lift for rough ground. Always check how much weight the lift can hold. Also check how high it can go. Safety features like guardrails keep you safe. Emergency stop buttons help if there is a problem. Check your lift every day to keep it working well.

Environment | Power Source | Best Features |

|---|---|---|

Indoor | Electric | Quiet, zero emissions |

Outdoor | Diesel/Tracked | Handles rough terrain |

Note: Jieyang Machinery has many scissor lifts, stackers, and hand winches. You can find the right tool for any job, inside or outside.

You are important for scissor lift safety. Only trained workers should use a scissor lift. Training teaches you how to spot dangers. You learn to use safety gear and follow safe rules. You must check the lift before you use it. Training shows you the risks of falling or tipping over. It also teaches about electric shock. You get practice and take safety tests. This helps you feel ready to use the lift. Always stay at least 10 feet from power lines. Do not go over the lift’s weight limit. This includes tools and materials.

Tip: Always wear a harness, hard hat, and shoes that do not slip when you use a scissor lift. These steps help stop injuries.

New safety rules have made training better. ANSI and OSHA now need safe use plans and rescue plans. You must also do risk checks. Digital tools give you safety info right away. These changes help stop accidents. They make scissor lift safety very important at work.

Checking and caring for your scissor lift keeps it safe. Before you use it, look at the wheels, tires, and brakes. Check the guardrails and hoses for damage. Test all controls and emergency stop buttons. Make sure they work right. If your lift uses a battery, check the battery and wires. Always look at the work area for things that could be dangerous. Watch for uneven ground, trash, or wires above you.

Look at the lift’s frame and welds for cracks.

Test emergency systems and check fluid levels.

Write down all care and repairs in a log.

Good care lowers repair costs and stops breakdowns. Only trained people should fix the lift. Never use a lift with broken or missing parts. These steps keep everyone safe at work. Jieyang Machinery has safe stackers and manual material lifts. They follow strict safety rules and help you work safely.

You need to start by thinking about your work environment. Ask yourself if you will use the scissor lift indoors or outdoors. Indoor jobs often need electric models because they are quiet and clean. Outdoor work may need rough terrain lifts with strong tires and stabilizers. Check the ground where you will use the lift. Smooth floors work best with standard tires, while uneven ground needs special support.

Think about how high you need to reach. Measure the height of your work area. Make sure the lift can go high enough. Also, check the weight you need to lift. Add up the weight of workers, tools, and materials. Pick a lift that can handle this load safely. Look at the space where you will use the lift. Narrow hallways or tight spots need compact models. Some jobs may need extra features like tool trays or extension decks for better productivity.

Safety tip: Always choose a lift with guardrails, overload sensors, and emergency stop systems. These features help prevent accidents.

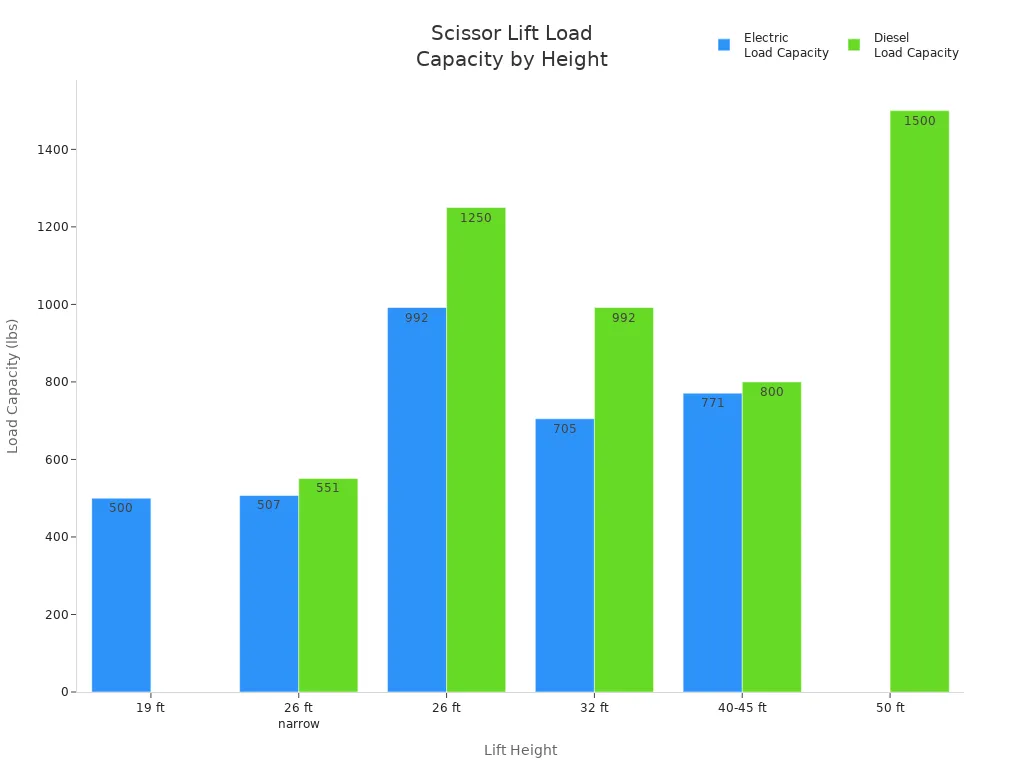

Different scissor lift models offer different heights, load capacities, and maneuverability. Use the table below to compare some common options:

Scissor Lift Height | Electric Load Capacity | Diesel Load Capacity |

|---|---|---|

19 ft | 500 lbs | N/A |

26 ft narrow | 507 lbs | 551 lbs |

26 ft | 992 lbs | 1,250 lbs |

32 ft | 705 lbs | 992 lbs |

40-45 ft | 771 lbs | 800 lbs |

50 ft | N/A | 1,500 lbs |

You can see that electric lifts work well for indoor jobs and lighter loads. Diesel models handle heavier loads and rough outdoor conditions. Some models are narrow and fit through tight spaces, while others have wide platforms for more workers and tools. Maneuverability depends on the width and drive type. Four-wheel drive models give you more stability on uneven ground.

Jieyang Machinery gives you many choices for lifting and handling equipment. You can find manual material lifts, stackers, and hand winches for different jobs. Their products work well in warehouses, factories, and construction sites. Jieyang Machinery designs each product for safety and easy use. You get strong platforms, reliable hydraulic systems, and helpful features like overload protection. The company offers excellent service and fast delivery. If you need advice, their team can help you pick the right model for your needs.

Note: Choosing Jieyang Machinery means you get quality, safety, and support for every lifting job.

You have learned how a scissor lift works and why safety is important. There are different types for different jobs. Experts say you should pick a platform that fits your work height, load, and where you use it. Always use guardrails and check the controls before you start. Jieyang Machinery has good scissor lifts, stackers, and hand winches for many kinds of work. You can ask them for help to choose the best mobile elevating work platform for your project.

You use a scissor lift to reach high places safely. It helps you work on ceilings, shelves, or equipment. Many people use it in construction, warehouses, and factories. Jieyang Machinery offers strong and reliable scissor lifts for many jobs.

You check your work height, weight needs, and space. Pick electric lifts for indoor jobs. Use hydraulic lifts for outdoor or heavy work. Jieyang Machinery can help you find the best manual material lift or stacker for your needs.

You must check the lift before use. Wear a harness and helmet. Stay inside the guardrails. Never overload the platform. Jieyang Machinery designs lifts with safety features like overload sensors and emergency stops.

You can use a manual material lift for lighter loads or smaller jobs. It works well in places without power. Jieyang Machinery offers many handling equipment options, including stackers and hand winches, for different lifting needs.

You can buy scissor lifts, stackers, and manual material lifts from Jieyang Machinery. Visit their product page to see all options. Their team helps you choose the right equipment for your work.